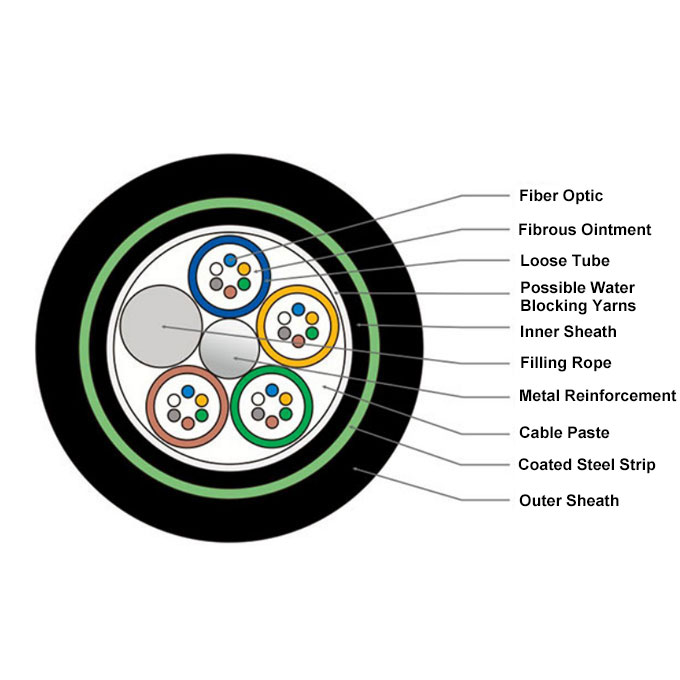

GYTY53 optical cable involves encasing optical fibers in loose tubes filled with gel. The core of the cable contains steel wires (possibly with a PE cushion layer), surrounded by loose tubes and filler ropes. Gaps inside and outside the core are filled with gel. The cable is extruded with a layer of polyethylene inner sheath, and after being longitudinally wrapped with dual-sided plastic-coated steel tape (PSP), it is extruded with a polyethylene outer sheath.

Number of optical fibers: 2 to 144 cores

Specific cable models include: GYTY53-24B1.3, etc.

Product Features:

Effectively protects optical fibers.

The cable structure design is very compact.

It has strong water resistance and moisture resistance.

It has excellent temperature characteristics.

It has strong tensile and pressure-resistant performance.

Performance Specifications of GYTY53 Optical Cable:

Allowable tension: Long-term 1000N, short-term 3000N

Allowable pressure: Long-term 1000N/100mm, short-term 3000N/100mm

Bending radius: Static bending radius 12.5 times the cable diameter, dynamic bending radius 25 times the cable diameter

Storage and operating temperature range: -40°C to +70°C

Meets standards: YD/T 901 and IEC 60794-1

Application: Outdoor backbone networks, local area networks, video surveillance, etc.

Installation methods: Direct burial, pipeline, non-self-supporting aerial installation

中文版

中文版 ENGLISH

ENGLISH