- Product description

-

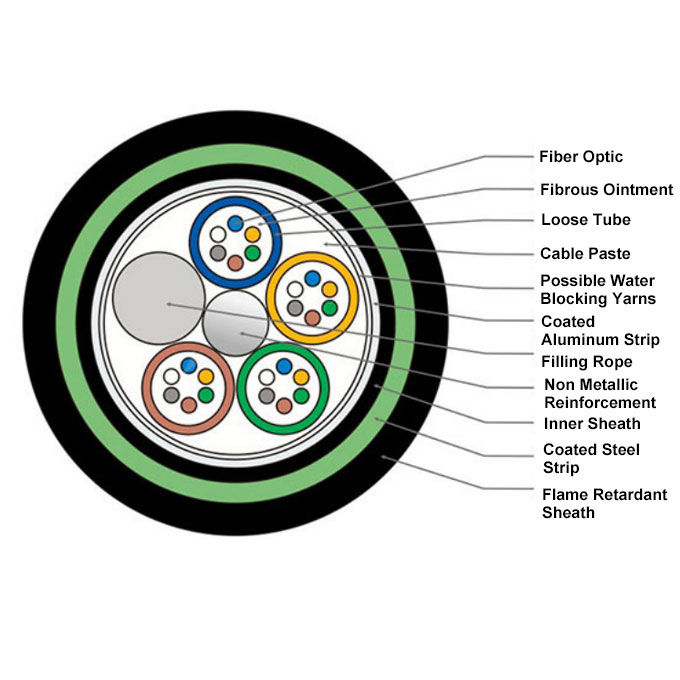

GYTZA53 optical cable involves placing optical fibers in a loose tube made of high-modulus material, filled with waterproof compound. The center of the cable core is a metal strengthening core. For certain fiber count cables, an extruded layer of polyethylene (PE) is added outside the metal strengthening core. The loose tube and filling rope are twisted around the central strengthening core to form a compact and circular cable core. Gaps inside the cable core are filled with water-blocking material. After longitudinal wrapping with aluminum-plastic tape (APL), an extruded layer of PE inner sheath is applied, followed by longitudinal wrapping with double-sided plastic-coated steel tape (PSP) and extrusion of flame-retardant outer sheath to form the cable.

Range of fiber counts: 2 to 144 fibers

Specific cable models such as: GYTZA53-24B1.3, etc.

Product features:

Effective protection of optical fibers.

Tight cable structure design.

Excellent mechanical performance and temperature characteristics.

Strong water-blocking and moisture-proof performance.

Excellent flame retardancy.

GYTZA53 optical cable performance indicators:

Allowable tension: Long-term 1000N, short-term 3000N;

Allowable crush resistance: Long-term 1000N/100mm, short-term 3000N/100mm;

Bending radius: Static bending radius is 12.5 times the cable diameter, dynamic bending radius is 25 times the cable diameter;

Storage and operating temperature range: -40~+70°C.

Meet standards: YD/T 1114 and IEC 60794-1

Application range: Outdoor trunk networks, local area networks, video surveillance, etc.

Installation method: Pipeline, aerial, direct burial

中文版

中文版 ENGLISH

ENGLISH