- Product description

-

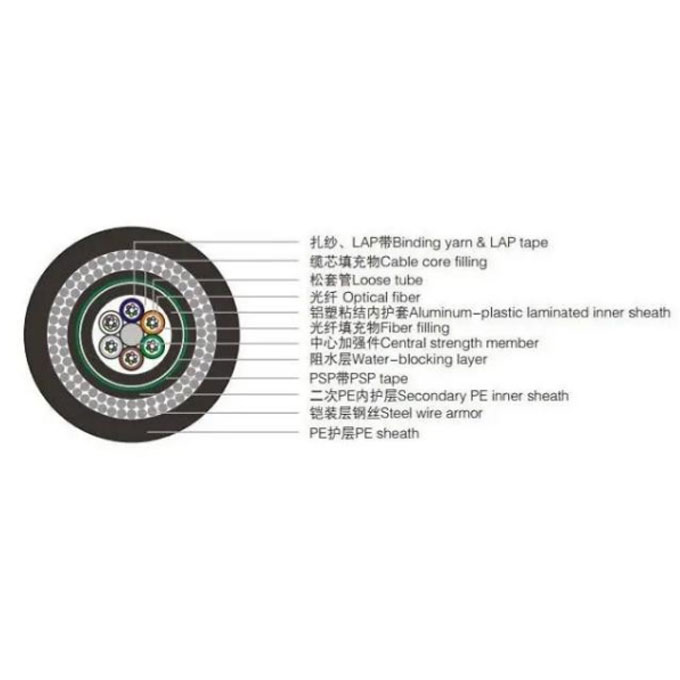

The structure of GYTA33 optical cable involves placing optical fibers in a loose tube made of high-modulus polyester material, filled with waterproof compound. The center of the cable core is a metal strengthening core. An extruded layer of polyethylene (PE) may be added outside the metal strengthening core as required. The loose tube and filling rope are twisted around the central strengthening core to form a compact circular cable core, filled with waterproof filler. After being longitudinally wrapped with aluminum tape, an extruded layer of PE inner sheath is applied, followed by longitudinal wrapping with double layers of fine round steel wire armor, and finally extrusion of a PE outer sheath to form the cable.

Range of fiber counts: 2 to 144 fibers

Specific cable models such as: GYTA333-24B1.3, etc.

Product features:

Effective protection of optical fibers.

Tight cable structure design.

Excellent mechanical performance and temperature characteristics.

Strong water-blocking and moisture-proof performance.

Double layers of fine round steel wire armor provide strong tensile and lateral pressure resistance for the cable.

GYTA333 optical cable performance indicators:

Allowable tension: "Long-term/short-term" is "10000N/20000N" or "20000N/40000N".

Allowable crush resistance: "Long-term/short-term" is "3000/5000" N/100mm or "4000/6000" N/100mm;

Bending radius: Static bending radius is 15 times the cable diameter, dynamic bending radius is 30 times the cable diameter;

Storage and operating temperature range: -40~+70°C.

Meet standards: YD/T 901 and IEC 60794-1

Application range: Suitable for long-distance communication, inter-office communication, CATV, and computer network transmission systems, etc.

Installation method: Underwater, direct burial, inclined installation

中文版

中文版 ENGLISH

ENGLISH