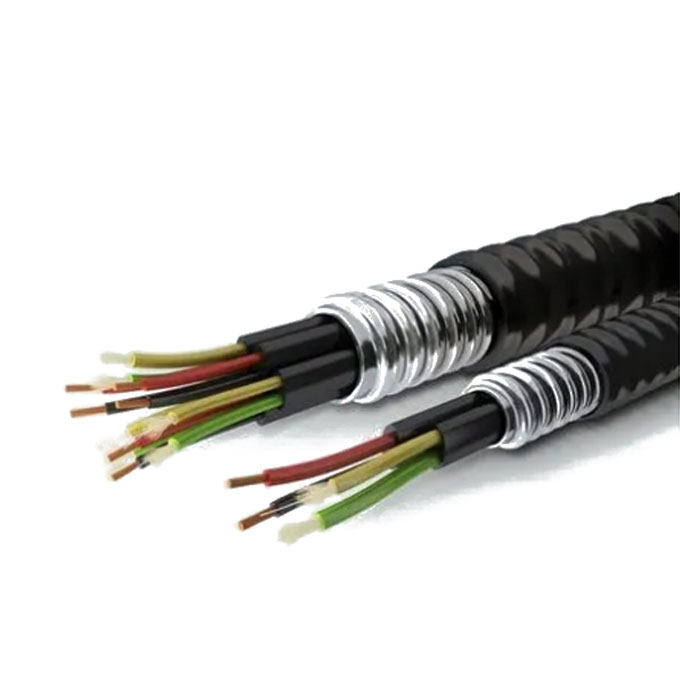

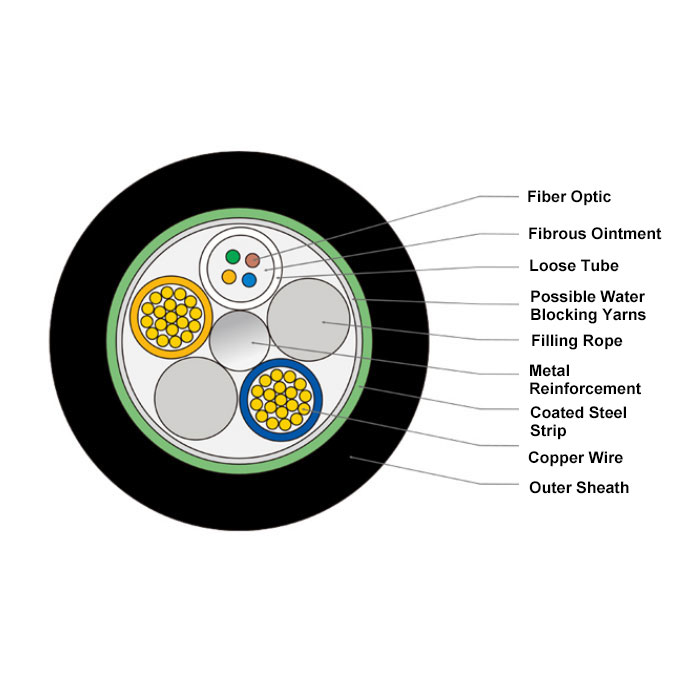

The structure of GDTS photoelectric composite cable involves placing single-mode or multi-mode optical fibers in a loose tube made of high-modulus polyester material, filled with waterproof compound. The center of the cable core is a metal strengthening core. For certain fiber count cables, an extruded layer of polyethylene (PE) is added outside the metal strengthening core. The loose tube and the required specifications of insulated copper conductors are twisted around the central strengthening core to form a compact circular cable core, filled with waterproof filler. After being longitudinally wrapped with double-sided chrome-plated plastic steel tape (PSP), it is extruded with a polyethylene sheath to form the cable.

Product features:

Integration of optics and electricity solves the problem of equipment power supply and signal transmission, providing centralized monitoring and maintenance of equipment power supply.

Improve the manageability of power supply, reduce power supply coordination and maintenance.

Reduce procurement costs and save construction costs.

Precisely controlled optical fiber surplus length ensures good tensile performance and temperature characteristics of the cable.

Storage and operating temperature range: -40~+70°C.

Application range: Mainly used in distributed base station DC remote supply systems, connecting BBU and RRU.

Installation method: Suitable for pipeline or aerial installation

中文版

中文版 ENGLISH

ENGLISH